Sale

Our quality

- Your advantage.

Your partner for peripherals in the die casting & plastics industry

We as FIMRO have been working since 1995 as a representative, service partner and manufacturer of peripheral equipment in the die casting and plastics industry.

We would like to show you that technical advice, sales, commissioning and service form a unit with us to your advantage.

FIMRO

Rinsing systems for

tempering

FIMRO

Cleaning systems for

spraying tools

FIMRO

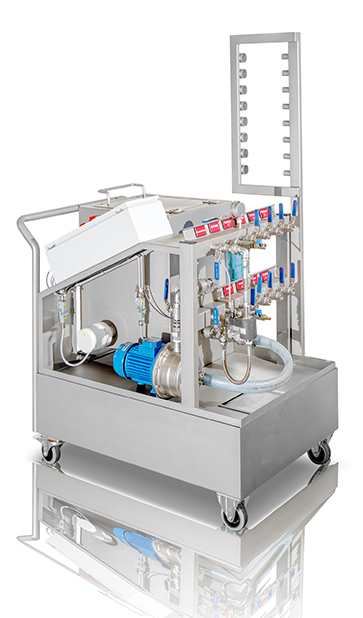

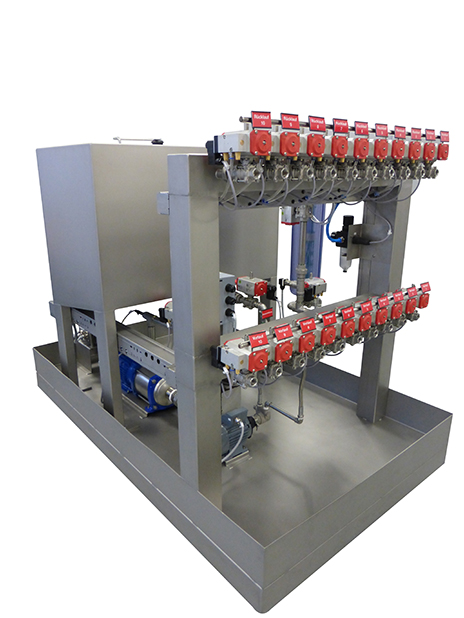

Rinsing systems for

tempering channels

For optimum temperature control of molds, the contact surface between tempering medium and mold steel is of crucial importance. Depending on the tempering medium and operating conditions, lime, rust or oil carbon form over time. These form deposits in the tempering channel, which narrow the cross-section of the channel and hinder the heat transfer between the forming steel and the tempering medium very much. Thus, there is a creeping increase in the heating or cooling times and a deterioration in component quality.

With our flushing systems, the impurities can be removed and thus the original heat transfer can be restored. In addition, our flushing systems can also control the flow and the tightness of the individual circuits and, depending on the system variant, can also be logged simultaneously. This can be done in the process of cleaning and thus represents a clear time savings compared to separate test stations.

The production of the equipment takes place completely in our company from construction to assembly. Thus, we are very flexible when it comes to special requests of our customers. Just contact us.

FIMRO

Cleaning systems for

spraying tools

Of crucial importance in the die casting process is the reproducible application of release agent to the mold surface. Due to the ingredients contained in the release agent, it comes creeping to enforce up to the closure of the spray nozzles of the spray tools. The resulting change in the molding compound has a direct negative impact on component quality and the die casting process.

For the targeted removal of these contaminants, the cleaning systems for spray tools were developed. Using a specially developed cleaning chemistry, the release agents are dissolved and removed in the spray tool. For this cleaning the disassembly of the spray tools is not necessary. This means a huge saving in personnel costs and the spraying tools remain completely intact in your design and thus provide the basis for a reproducible spraying process.

Our product range offers the ideal solution for almost all applications, yet we are always able to implement special requests. Just contact us.

Selling

program

Fondarex

In die casting and injection molding, vacuum technology is the most efficient way to evacuate the air and the developing gases in the mold cavity. This advantage helps prevent the negative effects of air in the mold cavity. As a pioneer in the field of vacuum technology in die casting and injection molding, FONDAREX systems, valves and chill blocks with their innovative technology, variability and excellent process monitoring offer the user the best opportunities for the production of high-quality parts.

Regloplas

As a specialist with many years of worldwide experience in the temperature control of processes, REGLOPLAS innovative products also offer the foundry all the advantages in terms of reliability and performance in the field of die casting. In addition to the large selection of temperature control units and temperature control systems for the respective application, special solutions designed to the wishes of the foundry are also possible at any time.

Wollin

In the area of spray technology for release agent application, WOLLIN with its spraying tools, sprayers and systems for the supply of release agent offers the foundry the optimum possibilities for the production of high-quality castings. But also in the field of automation and metal dosing WOLLIN has been able to demonstrate its innovative strength and reliability several times over.

Copromec

As a manufacturer of casting plungers, filling chambers and piston rods, COPROMEC has developed into an expert in the filling process of die casting. This is particularly evident in the large number of patents in this area that have been realized and proven in practice. With the aid of a coordinated system consisting of annular piston, filling chamber, piston rod and the new internal lubrication system, the service life of the components can be significantly increased and component quality can be positively influenced.

ROTH Hydraulics

Roth Hydraulics, formerly known as Bolenz & Schäfer, has been a leader in high-pressure storage technology for over 60 years. As a globally sought-after partner when it comes to technologies and innovations in the field of storage technology, Roth Hydraulics components can be found in many systems in the die casting industry.

MORGAN

Morgan Advanced Materials specializes in the production of refractory materials for the melting sector. This includes products such as crucibles, pyrometer protection tubes, impellers and other refractory materials. We offer our customers the possibility of a framework agreement and ensure the delivery of the agreed products from our warehouse. This eliminates the need for the customer's own expensive warehousing and the delivery time is significantly reduced.

MMP

Molten Metal Products (MMP) is a producer of crucible furnace plants in the Morgan group of companies. The production program covers the entire possible product range of heating types (gas, electric, oil and combined systems). In addition to transport ladles, tilting and crucible furnaces, special designs and a wide variety of sizes can also be realized.

Boss

Boss Lubricants develops and produces process fluids and specialty lubricants. A new anhydrous hydraulic medium HFDU was developed by a joint project of the companies Boss Lubricants, Bühler AG, Voit Automotive and FIMRO and successfully tested in serial production. As a result, among other things, the wear and corrosion of the hydraulic components are significantly reduced and saved by the improved lubricating properties energy. The hydraulic fluid HFDU represents a significant development over the known HFC.

Fimro rinsing systems for temperature control channels

For optimum temperature control of molds, the contact surface between tempering medium and mold steel is of crucial importance. Depending on the tempering medium and operating conditions, lime, rust or oil carbon form over time. These form deposits in the tempering channel, which narrow the cross-section of the channel and hinder the heat transfer between the forming steel and the tempering medium very much. Thus, there is a creeping increase in the heating or cooling times and a deterioration in component quality.

With our flushing systems, the impurities can be removed and thus the original heat transfer can be restored. In addition, our flushing systems can also control the flow and the tightness of the individual circuits and, depending on the system variant, can also be logged simultaneously. This can be done in the process of cleaning and thus represents a clear time savings compared to separate test stations.

The production of the equipment takes place completely in our company from construction to assembly. Thus, we are very flexible when it comes to special requests of our customers. Just contact us.

Fimro cleaning systems for spray tools

Of crucial importance in the die casting process is the reproducible application of release agent to the mold surface. Due to the ingredients contained in the release agent, it comes creeping to enforce up to the closure of the spray nozzles of the spray tools. The resulting change in the molding compound has a direct negative impact on component quality and the die casting process.

For the targeted removal of these contaminants, the cleaning systems for spray tools were developed. Using a specially developed cleaning chemistry, the release agents are dissolved and removed in the spray tool. For this cleaning the disassembly of the spray tools is not necessary. This means a huge saving in personnel costs and the spraying tools remain completely intact in your design and thus provide the basis for a reproducible spraying process.

Our product range offers the ideal solution for almost all applications, yet we are always able to implement special requests. Just contact us.

FIMRO cleaning of cartridge filters

With increasing contamination of filters, the flow rate continues to decrease. This has a direct influence on the temperature control behavior and thus on the part quality. With a specially constructed cleaning and test section, filters can be brought almost back to the quality level of new filters. The final inspection of each filter at the end of cleaning ensures that this is well done and recorded.

FIMRO contamination indicators for filters of temperature control units

We have developed an automatic filter contamination indicator to simplify maintenance. These are available as a mechanical variant with a green / red display or as an electronic variant. With this display, the contamination status of the filter can be assessed without having to open it. This significantly reduces downtimes and personnel costs.

Selling

partner

Fondarex

In die casting and injection molding, vacuum technology is the most efficient way to evacuate the air and the developing gases in the mold cavity. This advantage helps prevent the negative effects of air in the mold cavity. As a pioneer in the field of vacuum technology in die casting and injection molding, FONDAREX systems, valves and chill blocks with their innovative technology, variability and excellent process monitoring offer the user the best opportunities for the production of high-quality parts.

Regoplas

As a specialist with many years of worldwide experience in the temperature control of processes, REGLOPLAS 'innovative products also offer the foundry all the advantages in terms of reliability and performance in the field of die casting. In addition to the large selection of temperature control units and temperature control systems for the respective application, special solutions designed to the wishes of the foundry are also possible at any time.

Wollin

In the area of spray technology for release agent application, WOLLIN with its spraying tools, sprayers and systems for the supply of release agent offers the foundry the optimum possibilities for the production of high-quality castings. But also in the field of automation and metal dosing WOLLIN has been able to demonstrate its innovative strength and reliability several times over.

Copromec

As a manufacturer of casting plungers, filling chambers and piston rods, COPROMEC has developed into an expert in the filling process of die casting. This is particularly evident in the large number of patents in this area that have been realized and proven in practice. With the aid of a coordinated system consisting of annular piston, filling chamber, piston rod and the new internal lubrication system, the service life of the components can be significantly increased and component quality can be positively influenced.

ROTH Hydraulics

Roth Hydraulics, formerly known as Bolenz & Schäfer, has been a leader in high-pressure storage technology for over 60 years. As a globally sought-after partner when it comes to technologies and innovations in the field of storage technology, Roth Hydraulics components can be found in many systems in the die casting industry.

MORGAN

Morgan Advanced Materials specializes in the production of refractory materials for the melting sector. This includes products such as crucibles, pyrometer protection tubes, impellers and other refractory materials. We offer our customers the possibility of a framework agreement and ensure the delivery of the agreed products from our warehouse. This eliminates the need for the customer's own expensive warehousing and the delivery time is significantly reduced.

MMP

Molten Metal Products (MMP) is a producer of crucible furnace plants in the Morgan group of companies. The production program covers the entire possible product range of heating types (gas, electric, oil and combined systems). In addition to transport ladles, tilting and crucible furnaces, special designs and a wide variety of sizes can also be realized.

Boss

Boss Lubricants develops and produces process fluids and specialty lubricants. A new anhydrous hydraulic medium HFDU was developed by a joint project of the companies Boss Lubricants, Bühler AG, Voit Automotive and FIMRO and successfully tested in serial production. As a result, among other things, the wear and corrosion of the hydraulic components are significantly reduced and saved by the improved lubricating properties energy. The hydraulic fluid HFDU represents a significant development over the known HFC.

Fimro rinsing systems for temperature control channels

For optimum temperature control of molds, the contact surface between tempering medium and mold steel is of crucial importance. Depending on the tempering medium and operating conditions, lime, rust or oil carbon form over time. These form deposits in the tempering channel, which narrow the cross-section of the channel and hinder the heat transfer between the forming steel and the tempering medium very much. Thus, there is a creeping increase in the heating or cooling times and a deterioration in component quality.

With our flushing systems, the impurities can be removed and thus the original heat transfer can be restored. In addition, our flushing systems can also control the flow and the tightness of the individual circuits and, depending on the system variant, can also be logged simultaneously. This can be done in the process of cleaning and thus represents a clear time savings compared to separate test stations.

The production of the equipment takes place completely in our company from construction to assembly. Thus, we are very flexible when it comes to special requests of our customers. Just contact us.

Fimro cleaning systems for spray tools

Of crucial importance in the die casting process is the reproducible application of release agent to the mold surface. Due to the ingredients contained in the release agent, it comes creeping to enforce up to the closure of the spray nozzles of the spray tools. The resulting change in the molding compound has a direct negative impact on component quality and the die casting process.

For the targeted removal of these contaminants, the cleaning systems for spray tools were developed. Using a specially developed cleaning chemistry, the release agents are dissolved and removed in the spray tool. For this cleaning the disassembly of the spray tools is not necessary. This means a huge saving in personnel costs and the spraying tools remain completely intact in your design and thus provide the basis for a reproducible spraying process.

Our product range offers the ideal solution for almost all applications, yet we are always able to implement special requests. Just contact us.

FIMRO cleaning of cartridge filters

With increasing contamination of filters, the flow rate continues to decrease. This has a direct influence on the temperature control behavior and thus on the part quality. With a specially constructed cleaning and test section, filters can be brought almost back to the quality level of new filters. The final inspection of each filter at the end of cleaning ensures that this is well done and recorded.

FIMRO contamination indicators for filters of temperature control units

We have developed an automatic filter contamination indicator to simplify maintenance. These are available as a mechanical variant with a green / red display or as an electronic variant. With this display, the contamination status of the filter can be assessed without having to open it. This significantly reduces downtimes and personnel costs.