SPM 75

Small, compact system for a low number of temperature control channels.

- 2 circuits

- Flow measurement

- Pressure tightness measurement

- System pump with 70 l/min

- Mobile

- Manual

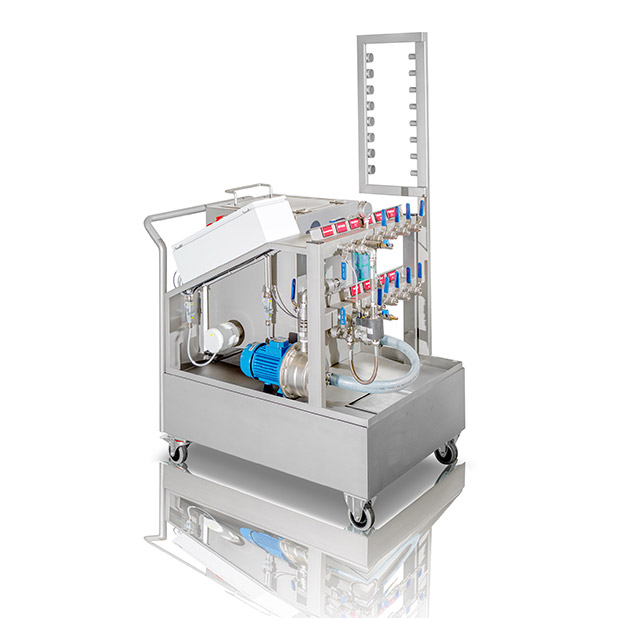

SPM 120

Medium-sized mobile system that combines all components in a small space. Ideal for a small to medium number of temperature control circuits and flexibly deployable.

- 4 circuits

- Flow measurement

- Pressure tightness measurement

- System pump with 70 l/min

- Mobile

- Manual

SPM 123

Medium-sized mobile system with the option of automatic program sequence.

- 6 circuits

- Flow measurement

- Pressure tightness measurement

- Frequency-controlled pump with 80 l/min

- Mobile

- Manual or automatic

SPM Custom Build

If none of the extensive SPM series meets your ideal requirements, we will gladly develop a suitable system for you.

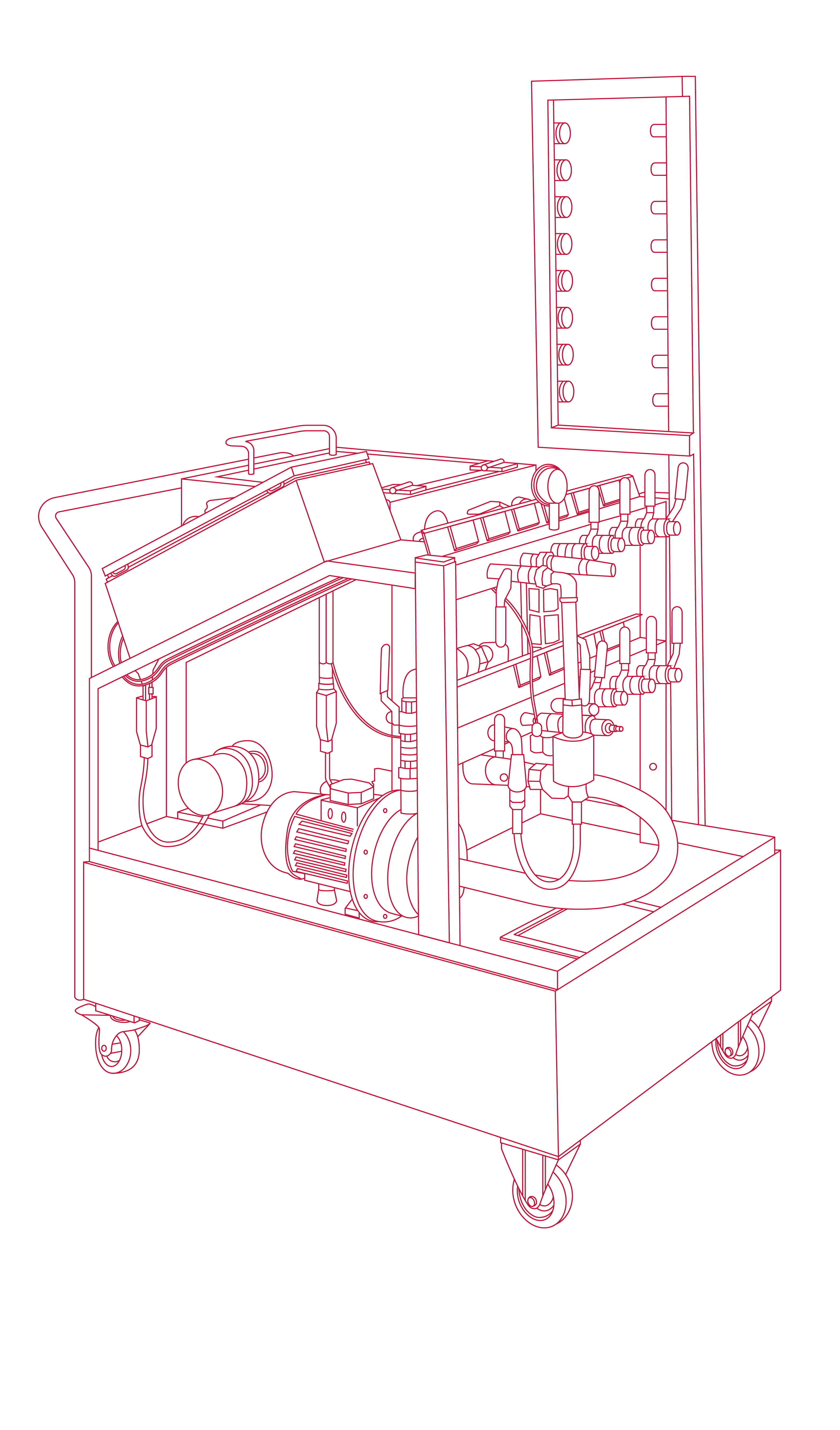

SPM 200

Largest mobile system, with the option of automatic program sequence.

- 8 to 12 circuits

- Flow measurement

- Pressure tightness measurement

- Frequency-controlled pump with 120 l/min

- Mobile

- Manual or automatic

Connection of the optional hose trolley